Plastiblow and sustainable plastic containers

The European strategy for the production of plastic in the circular economy and the contribution of Plastiblow Extrusion Blow Molding

It is useless to deny the importance that plastic plays as a material for various industrial processes and in everyday life, due to its characteristics of lightness, safety, protection, etc. But it is equally useless to deny how the environmental problem raised urgent considerations on its production, use and consumption. A culture of plastic waste and its recycling has been lacking and is still missing.

All countries and stakeholders, plastics producers, manufacturing companies, recycling managers, retailers and final consumers, were urged to face this problem by every possible means, to improve the chain of this important and indispensable sector.

In 2015, the European Parliament adopted a circular economy plan, committing itself to developing a strategy useful for facing the possible challenges for all phases of the chain, considering that within the EU the sector employs over 1.5 million people with a turnover that exceeded 340 billion euros (2015 figure), with the promise of achieving the important goal of recyclability of all plastic packaging by 2030.

Alternative plant-based, biodegradable raw materials made from recycled materials and bio-based polymers with greener credentials are being developed. There are projects to improve, strengthen and modernize the recycling chain.

In Plastiblow we have been engaged for some time in the search for a virtuous mechanism that can help mitigate this important problem:

- in the last 10 years new construction technologies were implemented in our extrusion blow molding machines allowing to reach the highest energy efficiency class

( 10+ Euromap 46.1 for a specific energy consumption ≤ 0.29 kWh/kg )

read https://www.plastiblow.it/en/machines

- we are committed to reducing the use of virgin plastic by developing multilayer co-extrusion technologies with the use of recycled materials for the production of containers

read https://www.plastiblow.it/en/focus-on/tech-news/ Circular economy and sustainable packaging. Plastiblow's commitment.

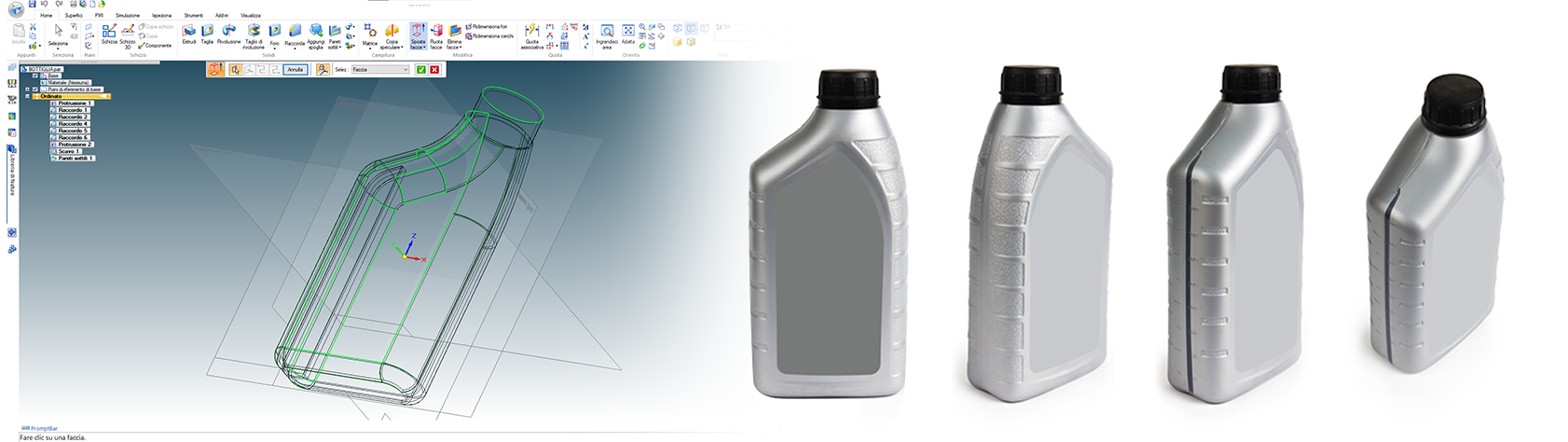

- we study for our customers the design of lighter containers (lower weight = less use of plastic) but equally safe for the products they must contain, even in multilayer solutions

read https://www.plastiblow.it/en/competences/design

It will take time, research, commitment, but the road towards a circular economy of the plastic sector has been taken. Many multinationals in the food, detergents and cosmetics industries are committed to switch to reusable, recyclable, compostable plastic packaging that uses greater quantities of regenerated materials.

At Plastiblow we are ready: today with our technologies we can obtain a final product with a layer of recycled material of 60/80% of the total thickness, enclosed between two layers of virgin material with a thickness of 10/20%, with a guarantee of safety and aesthetics for the consumer.

Ask for more information: plastiblow@plastiblow.it

.jpg)