Plastiblow: the quality of Made-in-Italy moulds

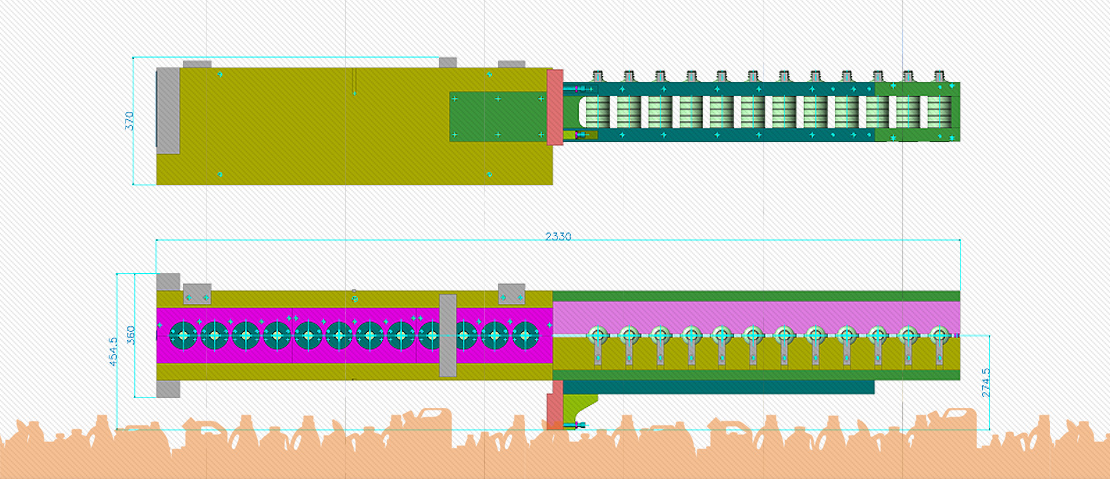

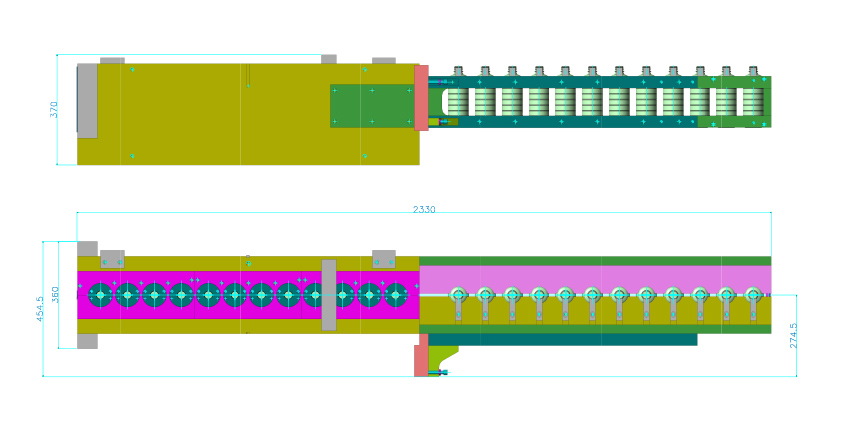

The knowledge of all the coextrusion blow moulding processes, including the criticalities, allows us to ensure the development of practically perfect moulds.

Producing low consumption electric blow moulding machines, means getting to know and be able to optimize every aspect of the whole project, including making the moulds.

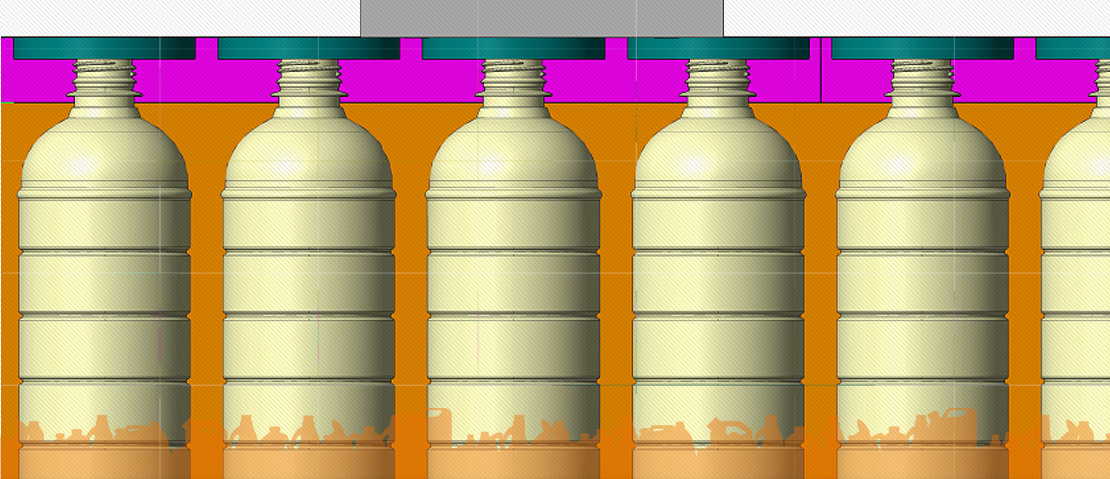

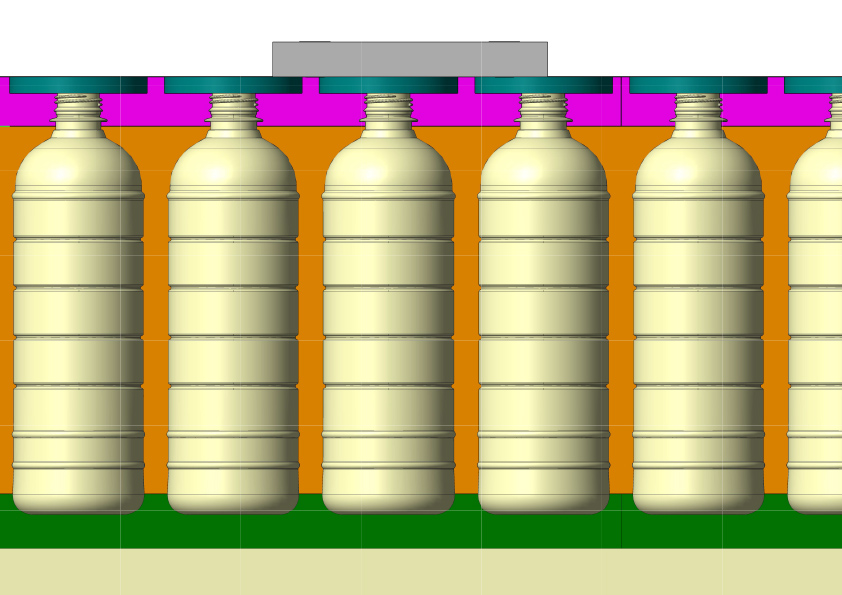

Moulds that are essential components for the perfection of the final product, especially if we talk about extrusion-blowmoulding processes that exploit the specific characteristics of different thermoplastic materials, which must make up a multi-layer structure.

The molds must withstand the worst possible conditions: high temperatures, high working speeds, minimum obtainable thicknesses, etc. They must also be able to integrate technologies such as IML (In-Mould Labeling) ensuring the capability to form the container.

Tel. +39 02 44 05 476

.jpg)